Galvanized steel plays a vital role in the automotive industry especially in exterior car parts so it must meet the highest quality standards.

At Tata Steel’s Immersion Galvanizing Line 3 in IJmuiden, Finishing Line 32 sets the benchmark in Europe. This is where slitting and painting processes are executed with precision, tailored exactly to customer specifications.

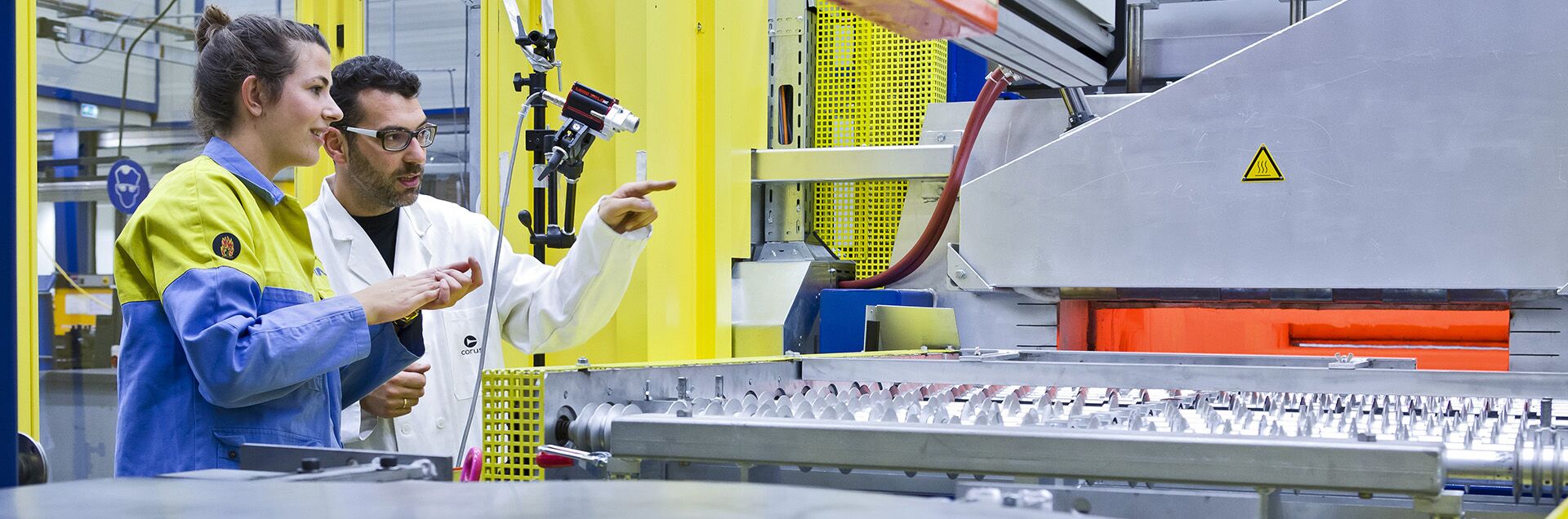

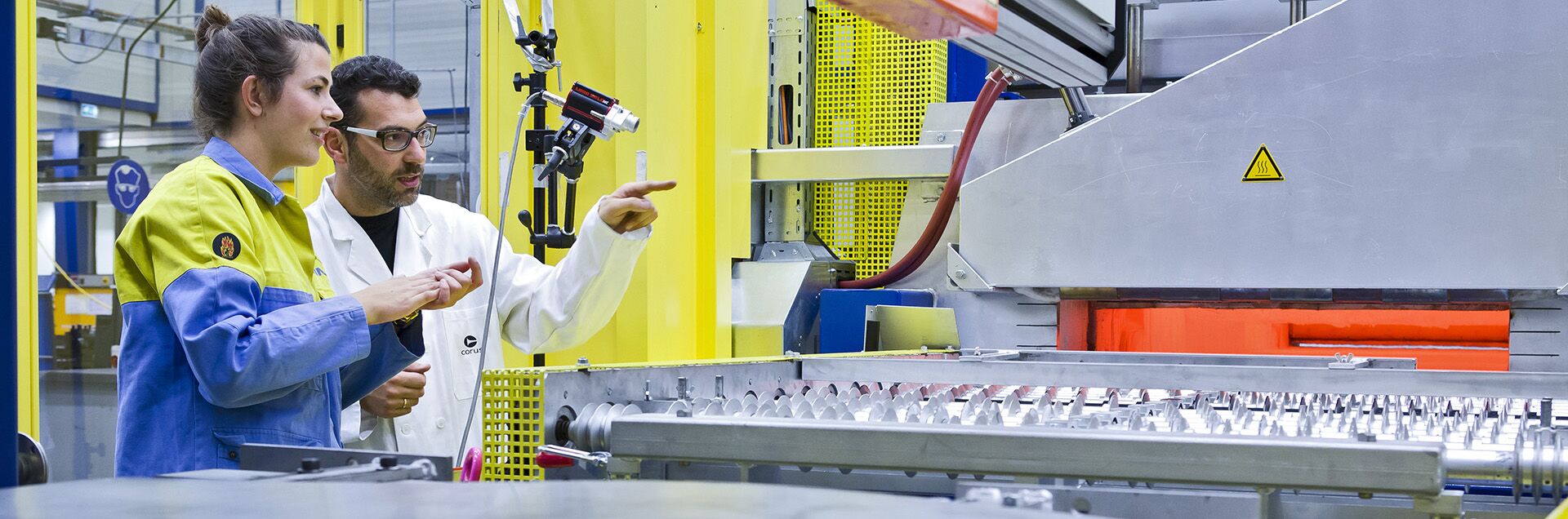

“This is where our Technical Management Team steps in,” explains Yusuf. “We ensure that this modern production line operates at its best. Slitting is the process of cutting a large steel roll the mother roll into two customer-specific rolls.”

But the work doesn’t stop there. Continuous improvements are also being made on the Paint Line, particularly in how the paint is dried in the ovens. Yusuf started his journey at Tata Steel as a maintenance trainee and became Maintenance Manager in 2013, now responsible for both the Paint Line and Finishing Line 32.

Since taking on the role, he has worked closely with the Technical Management Team and other specialists to optimize key components such as the hot air fans in the oven. These enhancements mark an important step toward greater energy efficiency, helping Tata Steel stay at the forefront of innovation and sustainability in steel processing.